Polyglass is known for innovation; it has become an industry-recognized trademark over the company’s 30 years of growth and success in the United States. One of Polyglass’ commercial system specialists, David Edwards, sat down with Heidi Ellsworth of the Roofers Coffeeshop Podcast to discuss these innovations and explicitly focus on our line of Kool Roof Solutions™, including our highly reflective, white Polyfresko® modified bitumen cap sheets.

So, what sets apart Polyfresko and Polyglass’ other industry-leading roofing solutions? Let’s find out.

What are Polyfresko Granulated Cap Sheets?

Currently, the patented, one-of-a-kind Polyfresko cap sheet range is one of Polyglass’ most innovative cool-roofing solutions, incorporating the last decade and a half of research and development.

Its differentiator is the Polyfresko line’s unique use of CURE® thin film technology on top of Polyglass’ APP- and SBS-modified bitumen membranes. This technology substantially improves roofing durability, reflectiveness, and membrane emissivity–distinguishing features for cool roofing materials.

CURE thin film provides enhanced performance without affecting the installation process. The white-tinted CURE thin film is applied during manufacturing to lock in the granules and improve granule adhesion. The innovation is also solvent-free, reducing environmental impacts.

The applied technology:

- Enhances protection and waterproofing

- Ensures complete granule retention

- Stabilizes ultraviolet (U.V.) rays

- Maintains surface integrity and reflectivity via minimized:

- Surface staining and discoloration

- Scuffing and other impact marks

- Torch scorching that can occur during installation

Let’s take a look at the top three benefits of the Polyfresko range.

Polyfresko Benefit 1: Ease of Installation

No innovation achieves widespread adoption—let alone topping its industry—without considering the ease of use. Regardless of how effective a roofing product is, the roofers who install it need to find the process as easy or easier than before. Easy installation is the case with all Polyglass products, as David learned when talking with the roofing contractors using Polyfresko.

“They know that whether they are installing it as a torch, APP, or SBS, it’s going to perform with the standards that they’re used to. And then they also love that Polyfresko comes in a self-adhered version as well.”

Self-Adhered Cool Roof Solutions

Polyfresko, with patented FASTLap® for end laps, can be installed with traditional heat welding and torch applications. However, the self-adhered (S.A.) versions feature one of Polyglass’ most groundbreaking innovations – ADESO® Self-Adhered Technology.

Self-adhering Polyfresko products feature a true APP or SBS top layer with the CURE thin film for maximum protection, while the aggressive, self-adhering ADESO formulation is applied beneath the reinforcement layer to streamline installation. No competitor has achieved comparable self-adhering white cap sheets. On the side laps, SA Polyfresko features Polyglass’s SEALLap® ULTRA to achieve an immediate, monolithic bond that has also tested stronger than all other installation methods.

Additional Benefits of Self-Adhered Technology

Eliminating heat welding and torch applications prevents the release of volatile organic compounds (VOCs), posing risks to roofers’ health and the environment. Plus, no pungent odor means that building occupants aren’t required to vacate the premise temporarily during restorations—which they and building owners certainly appreciate.

Across the board, SA Polyfresko offers improvements over comparable roofing materials while following a simple, three-step installation process:

- Align the sheet

- Peel off the release film

- Roll the sheet to ensure firm adhesion

Polyfresko Benefit 2: Effectiveness and SRI

If Polyglass’ products only led the industry in ease of installation, contractors and building owners would eventually consider alternatives. But they aren’t because the performance of Polyfresko products is also unmatched.

As David framed it, “When it comes to Polyglass and Polyfresko, the numbers—the initial SRI and the three-year SRI—exceed every other modified bright white cap on the marketplace today. And that is just something we’re super proud to be able to offer to the marketplace.”

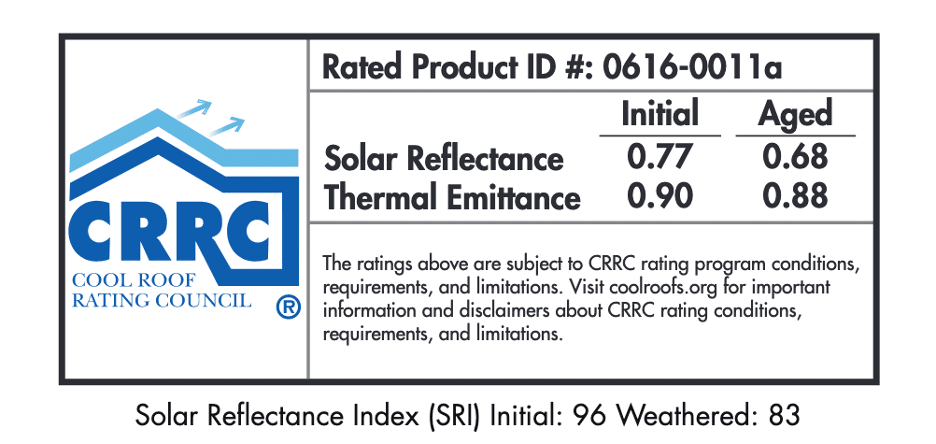

Information on roofing products’ solar reflective index (SRI) and other metrics is made publicly available by the Cool Roofs Rating Council (CRRC). The SRIs listed in the CRRC’s product directory have been assessed and validated by CRRC-1, their independent laboratory.

SRI Ratings and the CRRC

SRI ratings—particularly the “weathered” rating determined after three years—are the hallmark of a quality cool roof. Solar reflectivity is the amount of solar energy that a roof reflects, leading to reduced heat transfer inside the building and minimizing the amount of “heat islands,” particularly in urban areas. The better the SRI, the less energy is consumed for internal temperature regulation and the less solar energy retained within the local climate.

For both the initial and three-year ratings (96 and 83, respectively), Polyfresko products remain unsurpassed by any other product in the asphaltic membranes category—and more than half of all single-ply options.

According to David, building owners and roofing contractors have increasingly turned to single-ply products for reflectiveness over modified bitumen membrane’s durability. With Polyfresko, they can now achieve the best of both.

Polyglass Polyfresko membranes also meet or exceed industry code approvals; product-specific approvals for all our products can be viewed in our Product Data Sheets.

LEED Credits for Sustainable Sites and California’s Title 24 Part 6

Polyfresko will help building owners earn applicable credits toward Leadership in Energy and Environmental Design (LEED) certification for sustainable sites, overseen by the U.S. Green Building Council. In addition, the cool roof standards that Polyfresko achieves should also qualify for government rebates, whole-building incentives, and loans, which can be located on the CRRC’s dedicated page.

Per LEED v4.1, the latest version, low-sloped roofing materials must receive an initial SRI of 82 and a three-year SRI of 64—well below Polyfresko’s ratings. Polyfresko’s SRI also surpasses California’s requirements stipulated in Title 24 Part 6, which are the nation’s most stringent.

David’s enthusiasm for Polyfresko’s performance was evident on the podcast. “[T]here are cities, like Los Angeles City, that consider us the preferred bright white cap sheet because of those numbers alone. So it’s exciting,” he shared.

Polyfresko Benefit 3: Energy Reductions and Savings

As noted above, optimal SRI ratings translate to less energy consumption and expenditure (as with a reduced need for air conditioning). So, regardless of building code requirements and financial incentives during construction or renovation, many owners are turning to Polyglass products like Polyfresko because of these ongoing merits.

“The demand is rising because people are starting to realize what the real effect is on the energy savings for the building itself. The owners are requesting this at this point, and the designers also understand the importance of designing the systems accordingly,” David summarized.

Although anecdotal, David has also seen the energy savings firsthand.

“I personally have witnessed a cool roof go onto a school building that had two chillers running prior to the cool roof going on. And after the cool roof was installed, they were able to shut down a chiller,” David added.

Determining precise energy savings requires accounting for numerous variables, but tools like the Oak Ridge National Laboratory’s Cool Roof Calculator will help forecast them.

Only Growth on Polyglass’ Horizon

As the 30th anniversary of Polyglass US and our first manufacturing plant opening in Nevada, 2022 has been an exceptional year, one of which the Polyglass team is very proud. Polyglass’ plans for business growth and development over the next 30 years include expanded capacity, new manufacturing plants, and new product lines, including innovative waterproofing solutions and systems for below-grade structures.

If your interest in Polyfresko and Polyglass’ other innovative roofing and building envelope solutions has been piqued, contact us today to learn more!